In today’s fast-paced industrial world, the need for durable, long-lasting, and high-performance finishes on metal components is more critical than ever. From automotive and aerospace to construction and manufacturing, industrial coatings serve as a protective shield against corrosion, wear, and harsh environmental conditions. But achieving a flawless and long-lasting coating is not just about the paint or the powder—it starts with surface preparation. This is where surface treatment tanks come into play, forming a vital part of the coating process across various industries.

What Are Surface Treatment Tanks?

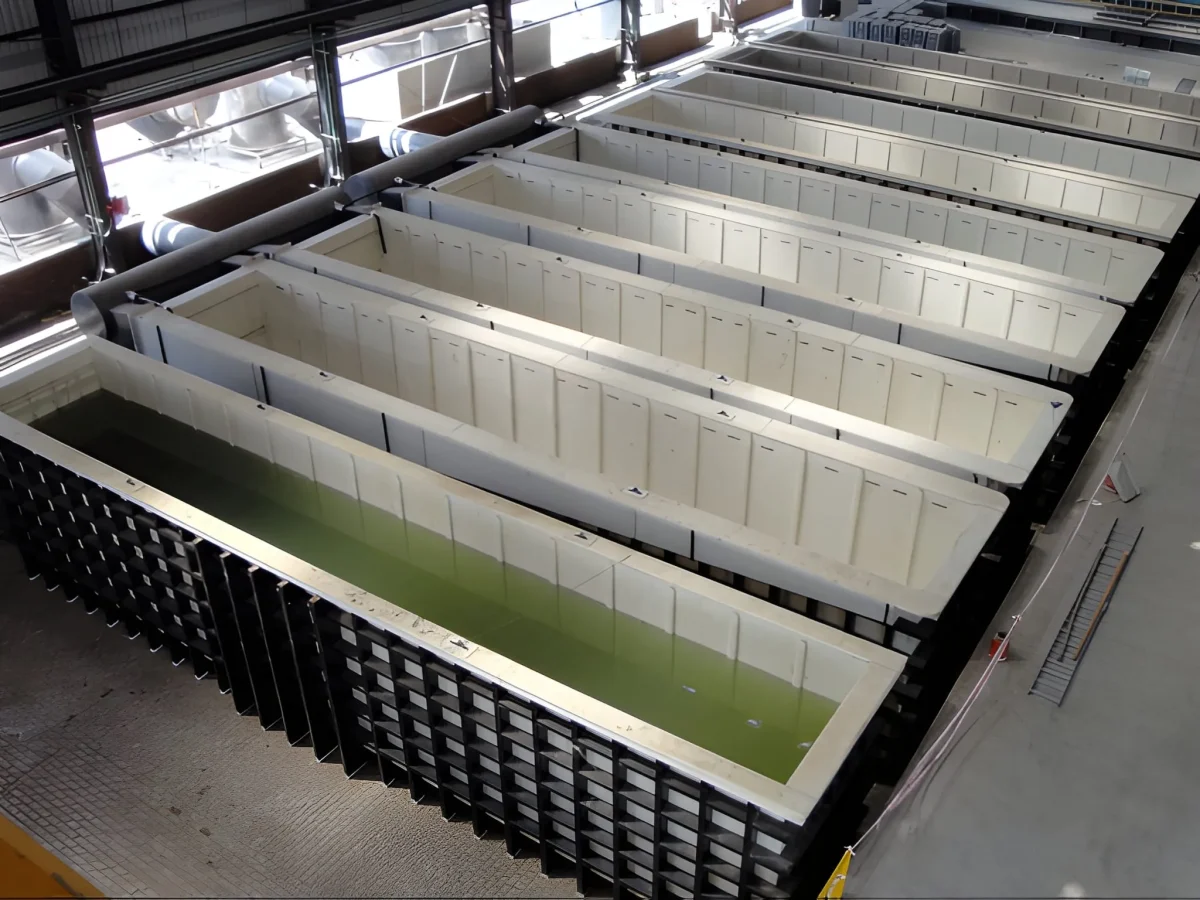

Surface treatment tanks are specially designed containers used to prepare metal surfaces before they receive any type of industrial coating. These tanks hold cleaning, degreasing, or chemical solutions that remove surface contaminants such as oils, rust, scale, or oxidation. This preparation is crucial for ensuring that the coating bonds properly to the substrate and performs as expected.

Depending on the application and type of coating, surface treatment tanks come in different types:

- Dip Tanks: Used for immersing metal parts into chemical baths for cleaning or pretreatment.

- Spray Tanks: Designed to spray chemicals onto parts, ideal for large or irregularly shaped components.

- Brush Tanks: Used in smaller operations where chemicals are applied manually using brushes for surface preparation.

Each type of tank serves a specific function and is selected based on the size, shape, and material of the components to be treated, as well as the volume of production.

Importance of Surface Treatment Tanks in Industrial Coatings

The quality of any industrial coating depends heavily on how well the surface has been prepared. Poor surface preparation often leads to coating failures like peeling, bubbling, cracking, or corrosion. Surface treatment tanks solve this issue by offering a controlled environment to treat the metal effectively before any coating is applied.

- Ensuring Proper Adhesion: One of the main purposes of surface treatment is to ensure proper adhesion between the substrate and the coating. Oils, dirt, oxides, or residues can create a barrier that prevents the coating from bonding securely. Surface treatment tanks eliminate these barriers, ensuring a clean and receptive surface.

- Removing Contaminants: Metal parts often arrive with residues from manufacturing processes, such as cutting fluids, greases, or rust, that must be removed before painting or powder coating. Surface treatment tanks allow forth complete removal of these contaminants, reducing the risk of defects and rework.

- Surface Preparation for Optimal Performance: Surface treatment tanks can also be used for processes like etching or phosphating, which create a textured or chemically active surface that improves the mechanical bond between the metal and the coating. This ensures the coating performs better under stress and environmental exposure.

- Improving Durability and Coating Quality: A properly prepared surface leads to more even coating application, increased durability, and improved aesthetic appearance. This directly affects product quality and customer satisfaction.

Benefits of Using Surface Treatment Tanks

Investing in high-quality surface treatment tanks delivers several long-term advantages for industries that depend on metal finishing and coating processes.

- Consistency and Uniformity: Surface treatment tanks provide consistent conditions for surface preparation, resulting in uniform cleaning and coating across all treated parts. This lowers variability, improves quality control, and assures that all products meet the same high expectations.

- Fewer Coating Failures: Improperly cleaned surfaces are prone to coating defects like blisters, adhesion loss, or corrosion underneath the coating. Using surface treatment tanks helps eliminate these risks, resulting in stronger and longer-lasting finishes.

- Higher Efficiency and Productivity: Automated or semi-automated surface treatment systems reduce the need for manual labor and allow multiple parts to be treated simultaneously. This increases production speed and decreases downtime, making the entire process more efficient.

- Long-Term Cost Savings: While there is an initial investment in surface treatment tanks, the long-term savings are significant. Fewer coating failures mean less rework, reduced material waste, and lower warranty claims. Also, enhanced coating effectiveness leads to a longer product life and lower maintenance costs.

Who is the Leading Surface Treatment Tanks Manufacturer?

STEP® Techno Solutions LLP is India’s leading manufacturer of Surface Treatment Tanks, providing high-quality solutions for a variety of industries including metal finishing and coating. With decades of experience and a strong reputation for innovation, STEP® Techno Solutions LLP offers a wide range of surface treatment tanks, including dip tanks, spray tanks, and custom-built systems.

As one of the most trusted Surface Treatment Tanks Manufacturers, the company uses materials like polypropylene, FRP (Fiber-Reinforced Plastic), and stainless steel to build tanks that resist corrosion, chemical damage, and wear over time. Their tanks are used in electroplating, powder coating, phosphating, and other industrial processes across sectors like automotive, railways, heavy engineering, and fabrication.

Each tank is designed to match the specific needs of the client, ensuring seamless integration into existing workflows. STEP® Techno Solutions LLP provides sturdy, dependable, and cost-effective solutions ranging from small workshop tanks to massive amounts industrial plant systems. They also offer expert installation, support, and after-sales service, making them the go-to partner for all your surface treatment needs.

Conclusion

Surface treatment tanks are an essential part of any industrial coating process. They ensure that the base material is perfectly cleaned, prepared, and ready to receive high-performance coatings. The benefits of using surface treatment tanks are clear better coating results, fewer failures, higher productivity, and long-term cost savings. Whether you are a small-scale fabricator or a large manufacturing plant, investing in the right surface treatment system is key to staying competitive in today’s demanding industrial landscape.

For high-quality, customized surface treatment tanks designed by technical expertise and reliable service, contact STEP® Techno Solutions LLP at +91 98988 75757 or email info@steptsl.com. Make the smart move toward cleaner surfaces, better coatings, and stronger performance.

FAQ

What is a surface treatment tank?

A surface treatment tank is a container used to clean and prepare metal surfaces before coating. It holds chemical solutions that remove dirt, grease, rust, and scale to ensure proper coating adhesion.

Why are surface treatment tanks important in coating processes?

They are essential because they ensure the surface is clean and reactive, allowing coatings to stick better, last longer, and resist damage from corrosion, moisture, or wear.

What types of surface treatment tanks are available?

Common types include dip tanks, spray tanks, and brush tanks. Each is designed for different shapes, sizes, and production needs, helping ensure thorough surface preparation before coating.

What materials are surface treatment tanks made from?

These tanks are usually made from polypropylene, FRP, stainless steel, or PVC. Each material offers resistance to specific chemicals and temperatures, ensuring durability and safety during use.

How do surface treatment tanks improve coating quality?

By cleaning and activating the surface, they help coatings bond properly. This results in smoother, more even coatings that perform better and last longer under tough conditions.

Do surface treatment tanks reduce coating failures?

Yes, they significantly reduce risks like peeling, bubbling, and poor adhesion by removing all surface contaminants before the coating process begins, ensuring consistent and reliable results.

Can surface treatment tanks help save costs?

Absolutely. It eliminate the need for revisions, reduce material waste, and enhance the lifespan of coated products—resulting in savings in the future for industries.

Where are surface treatment tanks used?

They are used in automotive, aerospace, construction, fabrication, and manufacturing industries—anywhere metals need to be coated, painted, plated, or treated for better durability.

Are surface treatment tanks safe to use?

Yes, when used with proper safety equipment and guidelines. High-quality tanks are built to properly handle corrosive chemicals and comprise features like fume coverings and drainage mechanisms.

Who is a reputable producer of surface treatment tanks in India?

STEP® Techno Solutions LLP is a leading manufacturer of surface treatment tanks in India, offering customized, durable, and high-performance tanks for all industrial coating needs.