Plant

Products

Services

STEP® TECHNO SOLUTIONS LLP

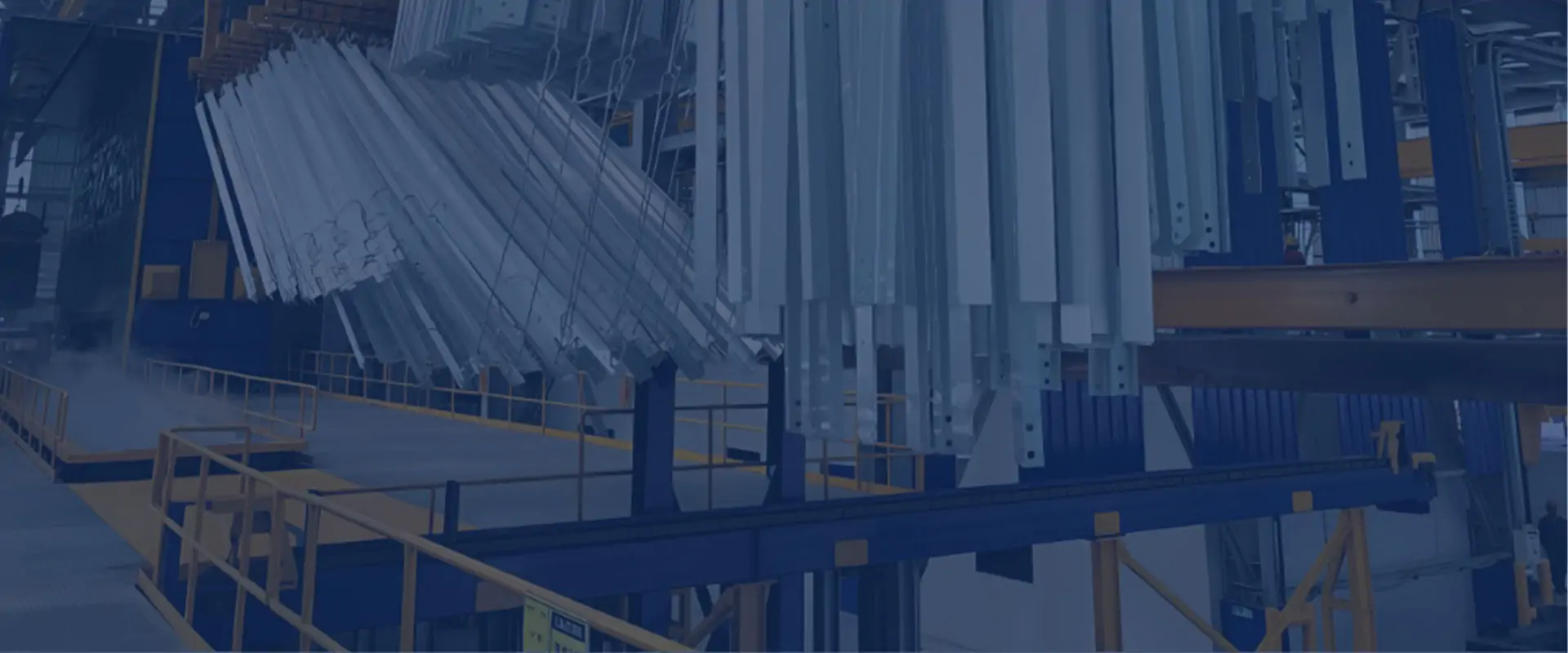

Turnkey Hot Dip Galvanizing Plant Manufacturer

At STEP® TECHNO SOLUTIONS LLP, we pride ourselves on our extensive expertise across various field, including manufacturing processes, design and engineering, plastic and metal fabrication, project management, surface treatment chemistry, and process automation. This diverse knowledge enables us to offer a comprehensive range of products, services, and solutions suited for the successful implementation of surface treatment projects. We specialize in large-scale turnkey solutions, managing all aspects of Engineering, Procurement, and Construction (EPC) from project inception to completion, ensuring seamless execution and high-quality outcomes.

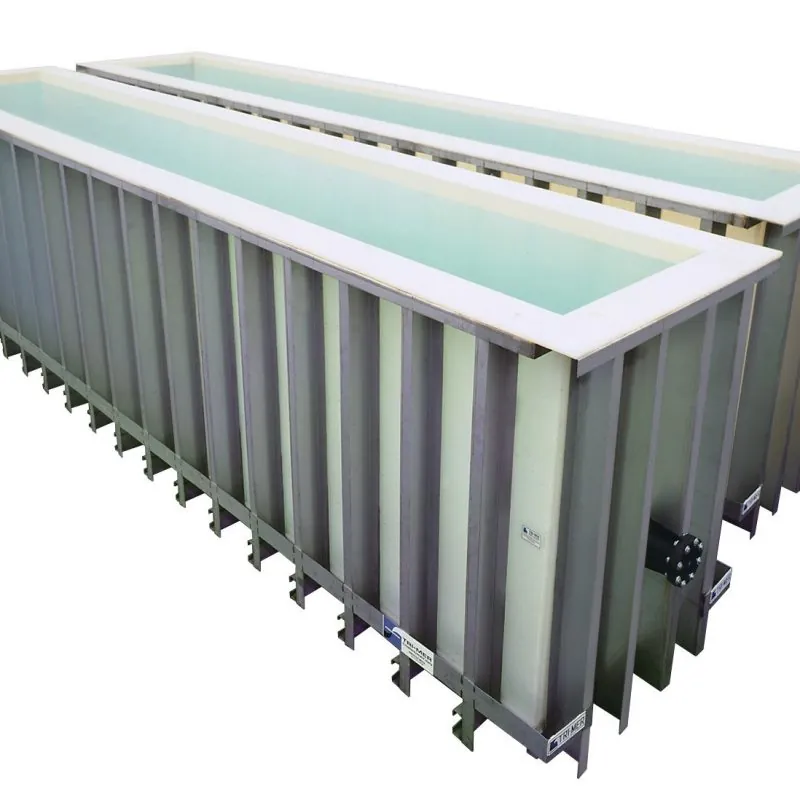

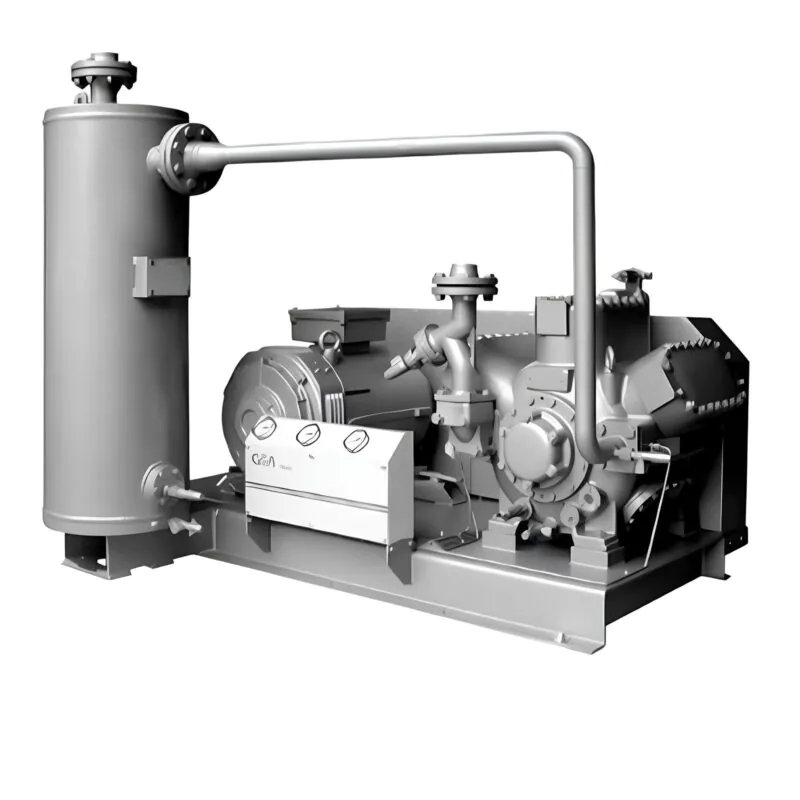

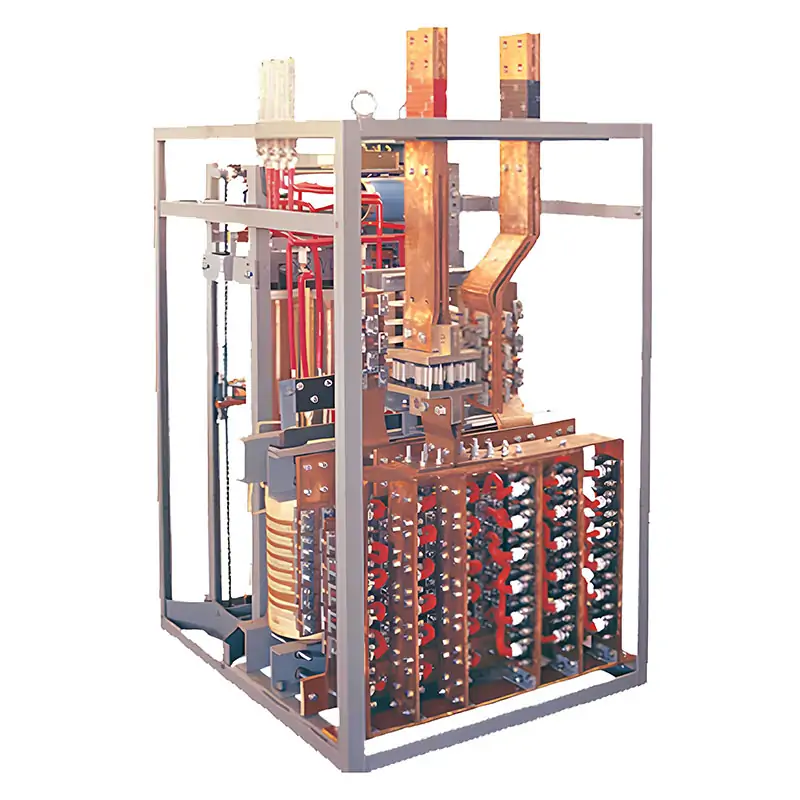

Our commitment to excellence is shown by our wide range of innovative solutions, specifically designed and manufactured to meet the specific needs of the surface treatment industry. As a leading manufacturer and exporter, we offer a variety of specialized plants and equipment, including Hot Dip Galvanizing Plants, Anodizing Plants, Electroplating Plants, Pickling Plants, Powder Coating Plants, and Phosphating Plants. Each of these products is engineered to meet the highest standards of efficiency, reliability, and performance, ensuring superior surface treatment solutions for a variety of industrial applications. At STEP® TECHNO SOLUTIONS LLP, our focus is on providing world-class products and services that support our clients' needs in surface treatment processes. We are committed to the continuous improvement of our offerings, ensuring that each project we undertake is completed with the utmost precision and care.

Our Plants

Surface Treatment Plant Manufacturer

Years Of Expertise

Happy Customers

Team Members

Quality Products

Products Used in Many Industries

Delivering innovative, reliable solutions tailored to diverse industrial needs and applications.

Collaborations

Kingfield-STEP® is a collaboration of Kingfield Technologies and Equipment based in Melbourne, AUSTRALIA and STEP® Techno Solutions based in Ahmedabad, INDIA for Hot Dip Galvanizing Plant in INDIA

With over 75 hot dip galvanizing plants set up worldwide, KTE is considered the most technologically advanced hot dip galvanizing plant designer and manufacturer

Bringing the best of the expertise of KTE Galvanizing Technology and STEP® Engineering to bring World Class Processes for Hot Dip Galvanizing Industries in INDIA.