STEPsaver® Flux Heating Systems Manufacturer

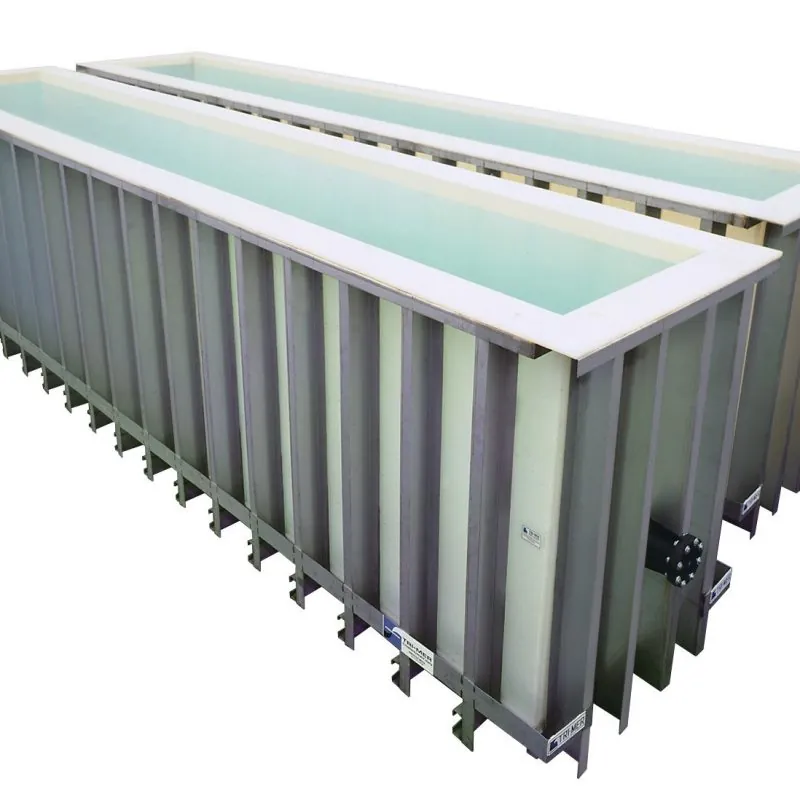

STEP® Techno Solutions LLP is a trusted manufacturer of STEPsaver® Flux Heating Systems, Industrial Flux Heating Systems, designed to maintain the flux solution temperature between 60°C to 80°C, a critical range for effective galvanizing. Keeping the flux solution at this temperature minimizes zinc splashes, reduces ash formation, and ensures a uniform, high-quality layer over the material’s surface.

The advanced STEPsaver® flux heating systems by STEP® Techno Solutions LLP ensure uniform heating across the tank with automatic temperature control, leading to consistent and efficient fluxing. These systems feature a multi-tube pipe-type heat exchanger made from seamless SS 316L tubes, utilizing hot quenching water from the quench tank to heat the flux solution. The quenching water, maintained at 80°C, circulates through the heat exchanger installed on the flux tank’s side, providing precise and even heating.

To prevent damage during steel dipping, the heat exchanger is shielded with a durable polypropylene perforated sheet. Unlike traditional designs that restrict heat exchanger placement to one tank end, ensures uniform heating throughout the tank, enhancing galvanizing quality.

An added advantage of this system is its maintenance-free design. The simple structure allows easy cleaning of scaling deposits, ensuring smooth water flow without blockages, delivering reliability and superior performance for industrial galvanizing processes.

Additional Information

- High energy efficiency, reducing power consumption and operational expenses.

- Durable construction for prolonged service life and minimal maintenance.

- Advanced temperature control for precise heating applications.

- Customizable solutions to meet specific industry requirements.

- Environmentally friendly, with reduced emissions and enhanced energy utilization.

- Reliable after-sales support and service for uninterrupted operations.

- Built-in safety mechanisms to ensure secure operations.

- Compact design, optimizing space usage in industrial setups.

- Robust materials and construction, suitable for demanding environments.

- User-friendly interfaces for easy operation and monitoring.

- Integration capabilities with modern industrial automation systems.

- Compliance with international quality and safety standards.

- STEPsaver® systems are the go-to choice for industries seeking efficient, cost-effective, and reliable heating solutions.